Ceramic Materials

CERAMIC MATERIAL

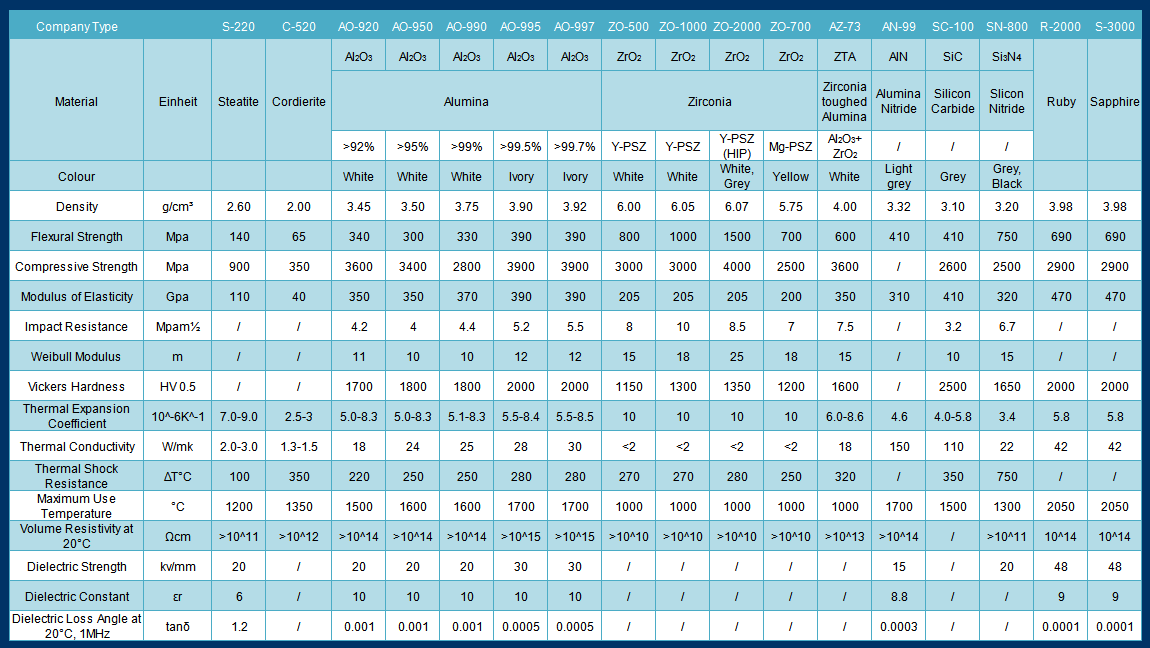

Physical Properties

Yixing Success Technical Ceramics Co.,Ltd.

Engineering Data is representative. Property values vary somewhat with method of manufacture,size and shape of part.

Alumina

Alumina is the most mature of the engineering ceramics, offering excellent electrical insulation properties together with high hardness and good wear resistance but relatively low strength and fracture toughness. It is applied, where a high wear resistance, good corrosion resistance and mechanical strength are necessary. Due to its strong electric and dielectric properties it is often applied for high voltage applications and electronic products.

The most common material used for structural ceramic parts is alumina. It is used in applications from aerospace to medical, from bearings to analytical instrumentation. High purity alumina ceramics lends itself well to corrosive environments.

Zirconia

Zirconia is excellent engineering ceramic by its desirable physical properties such as extremely high melting temperature, high strength and fracture toughness. Zirconia is applied where mechanical strength is required. A high impact resistance, flexural strength and hardness make it ideal for tough and rugged usage. The very low thermal conductivity makes it an ideal material for thermal insulation of high stressed mechanical parts.

Due to its thermal expansion coefficient close to steel, it is ideal for replacing metal machine parts in existing designs.

Yttria Stabilized Zirconia (YTZP) is the strongest ceramic material we offer. YTZP is a purely tetragonal phase, fine grain material. This material offers the highest flexural strength of all Zirconia based materials. YTZP exhibits a trait called transformation toughening which allows it to resist crack propagation. Applied stress, magnified by the stress concentration at a crack tip, can cause the tetragonal phase to convert to monoclinic, with the associated volume expansion.

This phase transformation can then put the crack into compression, retarding its growth, and enhancing the fracture toughness. This mechanism significantly extends the reliability and lifetime of products made with stabilized zirconia. YTZP is well suited to replacing metals due to its extremely high strength and toughness, it also offers far higher resistance to chemicals and superior erosion resistance.

Zirconia Toughed Alumina

ZTA is a composite ceramic material, which combines the advantages of Alumina and Zirconia. The Alumina guarantees the low price, good electrical and chemical properties as well as its hardness and wear resistance. The Zirconia toughens the material which results in a higher strength and impact resistance. Thus it is the ideal material for applications, where the mechanical load is not suitable for conventional Alumina ceramics.

The main advantage of Zirconia Toughened Alumina (ZTA) is the additional strength and toughness over alumina with a lower cost than zirconia (YTZP, MSZ, CSZ).

The combination of aluminum oxide and 10-20% zirconium oxide provides a much higher strength, toughness, hardness and wear resistance than alumina alone.

The 20-30% increase in strength often provides the design criteria needed at a much lower cost than using zirconia.

A process called transformation toughening is the phenomenon that increases the fracture toughness of ZTA. When placed under stress, the zirconia particles change their crystal structure from a tetragonal to a monoclinic structure, causing a volume expansion that compresses the surrounding crack in the alumina matrix.

ZTA should be considered for any application where structural strength is needed that exceeds the standard alumina properties.

Silicon Carbide

Silicon carbide has the highest corrosion resistance of all the advanced ceramic materials. It also retains its strength at temperatures as high as 1400°C and offers excellent wear resistance and thermal shock resistance.

Silicon Nitride

Silicon nitride has better high temperature capabilities than most metals combining retention of high strength and creep resistance with oxidation resistance. In addition, Silicon Nitride has an excellent thermal shock resistance. In combination with high strength, toughness, wear resistance, and good corrosion resistance, Silicon Nitride is often used in aerospace or automotive applications. Other applications are burner nozzles, molten metal processing, welding devices, machine parts, etc.